Phase – Changing Material Suit

Sanbir R., Jade T., Nathan K., Mubdi S., Carl E.

Writing for Engineering

The City College of New York

December 10th, 2018

Abstract

Phase-changing material (PCM) absorbs heat from the surroundings and releases it in the form of latent heat. A method of weaving PCM into fabrics has been utilized to create a wetsuit that is comfortable to wear and controls body temperature based on the environment. Various fabrics such as nylon, denim, and latex have been experimented with and are known to work with PCM. The final suits will cost $400 for the rubber version, $800 for the stretch denim version, and $1100 for the nylon version. The suit is designed with many promising capabilities and mass production will begin soon.

Table of Contents

Abstract…………………………………………………………………………………………………..2

- Introduction……………………………………………………………………………….……..4

- Objectives……………………………………………………………………………………….5

- Plan of Action………………………………………………………………….……………….6

- Design

- Fibers

- Management Plan…………………………………………………………….……………….7

- Conclusion……………………………………………………………………………….……..8

- References………………………………………………………………………..…………….9

- Introduction

The PCM material absorbs and releases thermal energy in an efficient way. When a PCM is solid, it absorbs heat until it equals the environment’s temperature. Once it reaches the melting point, the PCM will melt and thus change its phase to liquid. Conversely, when PCM is at a liquid state, it releases heat in the form of latent heat. The PCM in the fiber change phases according to the temperature of the human body (Lotens, p.1, n.d.).

The way the PCM absorbs and conserves heat depends on the air that is trapped in and on the clothing. The PCM changes phase depending on the heat quality of the surroundings. A technique called bi-component melt spinning allowed for PCMs to be integrated into fibers (CORDIS, p.1, 2011). The fibers can be knitted and woven into various fabrics such as nylon and denim. Fabrics retain their thermal properties after wash cycles and prevent leakage of PCM to the environment.

Figure 1: PCM bubbles surrounded by Figure 2: PCM bubbles weaved into fabrics

clothing fibers (Lipol, 2016) on a microscopic level (Lipol, 2016)

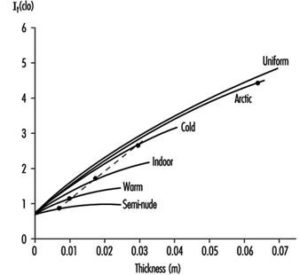

As a fabric gets thicker, the vapor resistance of the fabric increases proportionally. Since the PCM material would be woven into fabrics in microscopic capsules, the problem of insulation would be circumvented. PCM could be placed into virtually any fiber, thick or thin, and result in the same level of insulation. Since the PCM suit covers the whole body, it would create the maximum insulation by distributing latent heat energy throughout the body.

Figure 3: Relationship between fabric thickness and vapor resistance for fabrics. (Lotens, n.d.) Figure 4: Total insulation resulting from distribution of heat. (Lotens, n.d.)

II.Objective

The PCM suit’s main goal is to introduce a piece of clothing that can be worn throughout the year, in any environment while maintaining body temperature. The suit is designed to be comfortable enough to be worn either as an undergarment or an outfit itself. In efforts to remain eco-friendly, the suit will be offered in different clothing fibers. PCM promises to conserve and release heat in response to the consumer’s body temperature within the PCM suit and to hopefully establish a temperature regulated clothing brand.

III. Plan of Action

- Design

The basic design of PCM suit will be like a wetsuit with bubble wrap. The cloth will consist of 2 layers, where the inner layer will be the layer that contains phase-changing materials. The layer will have microscopic capsules that contain PCM. The outer layer will be made out of one of the 3 fibers, nylon/spandex, stretch denim or rubber/latex. The main purpose of the outer layer is to prevent PCM to interact with the environment and protect the capsules from being damaged. Furthermore, these capsules will restrict the movements of the material and isolate them for even distribution throughout the suit. If the phase-changing material is present in a single layer, the material can slide and get concentrated towards the bottom of the suit due to gravitational force. Also, because the physical state shifts, the layer can be destroyed due to change in volume. For these kinds of reasons, the material has to be separated into microscopic capsules.

- Fibers

Nylon/Spandex

The benefits of using nylon/spandex include elasticity and the freedom to move throughout various daily tasks. It is a lightweight material and resists damage from most oils that the consumers may come across. However, nylon can melt if exposed to very high temperatures. In addition, washing can cause “piling” of the fabric as it is too thin.

Stretch Denim

Stretch denim is relatively durable enough to protect the PCM bubbles. It would also contain about 2% of elastane making the material easy to move around in. Since it is a thick material, it may limit the user’s speed. It can also shrink when dried improperly.

Rubber/Latex

Rubber is strong enough to protect the bubbles and is a more natural fiber. It provides the most stretch out of all the fibers listed. However, it comes at a cost of comfort and many people have latex allergies which can result in mild skin rashes.

- Management Plan

The PCM suit will come in three options for consumers. As shown in the Production slide of our PCM Suit Powerpoint, the cheapest option will be the rubber suit, the medium option will be the suit made of stretch denim, and the most expensive suit will be made of nylon/spandex fabric. Our ideal hope is to have the suit mass manufactured by laborers in a factory who will sew the layers fabrics and fibers together. These laborers won’t need any special qualifications, we will provide ample instruction on putting together the suit.

Without a prototype handy, we can’t say how many pounds of PCM material are required for the suit, and without speaking to a manufacturer, it’s hard to get a quote for labor/production costs. However, we can make an early estimate for the average costs for a suit’s fabric material. According to a study by the Centers for Disease Control and Prevention, the average man is about 5’9.1” tall, and the average woman about 5’3.7” tall (CDC). Averaging this to about 5’6.4” per person, and taking into account wingspan, we estimate that we’ll need an average of 11 feet of fabric per suit. Rubber PCM suit materials will cost $5.28 per suit, the stretch denim material will cost $27.39, and the nylon/spandex material will come out to $32.89 per suit.

Keeping in mind that we don’t have a quote for manufacturing, and that the suit will utilize state-of-the-art technology and dynamics, we estimate the final prices that the PCM suits will sell for are about $400 for the rubber suit, $800 for the stretch denim suit, and $1100 for the nylon/spandex suit. With the state-of-the-art technology and the usefulness of the PCM Suit’s function, consumers will understand these are fair prices, and for our interests, they will also turn in a sufficient profit.

- Conclusion

PCM was founded by undergraduate engineering students attending the Grove School of Engineering at City College. Given that the students are freshly educated with the chemical aspects of PCM, the design of the suit will grant a more promising function. That is to say, all possible mishaps with the smart cloth were initially taken into consideration when designing the suit. In addition, there were several techniques proposed by the engineers, where the most effective was chosen. Also given that this suit is their first engineering proposal, they are more passionate about the functionality rather than the business. The suit has promising capabilities and we hope that one day it will be mass produced for all consumers to buy.

- References

Alibaba. (2018). Rubber Fabric For Sewing / Nylon Rubber Coated Fabric / Fabric Backed Rubber – Buy Neoprene Textile Fabric,Neoprene Fabric Roll,Rubber Fabric For Sewing Product on Alibaba.com. Retrieved from https://www.alibaba.com/product-detail/rubber-fabric-for-sewing-nylon-rubber_60769167433.html?spm=a2700.7724857.normalList.26.52bffb6dDde5LA

Alibaba. (2018). Sodium Sulphate Decahydrate – Buy Sodium Sulphate,Glaubers Salt/sodium Sulfate,Sodium Sulphate/mirabililte Product on Alibaba.com. Retrieved from https://www.alibaba.com/product-detail/Sodium-Sulphate-Decahydrate_60751755004.html?spm=a2700.7724857.normalList.2.d57c36ba93PzPo&s=p

CDC, N. (2018). FastStats. Retrieved from https://www.cdc.gov/nchs/fastats/body-measurements.htm

CORDIS. (2011, March 29). Smart fibres for body temperature regulation | Result In Brief. Retrieved December 3, 2018, from https://cordis.europa.eu/result/rcn/86417_en.html

Direct, F. (2018). Matte Milliskin Tricot. Retrieved from https://www.fabricwholesaledirect.com/collections/nylon-spandex-fabrics/products/matte-milliskin-tricot-fabric?variant=47382750732

Direct, F. (2018). Stretch Bull Denim (10 oz). Retrieved from https://www.fabricwholesaledirect.com/products/stretch-bull-denim-fabric?variant=9978331922547

GoldStarTool. (2018). Zippers – Lightweight Nylon #3 Coil Zipper – GoldStarTool.com. Retrieved from https://goldstartool.com/Zippers-Coil-size_3.html

Lipol, L. S. (2016, November 17). Characterization of the PCM fibers. Retrieved December 3, 2018, from https://www.textiletoday.com.bd/characterization-pcm-fibers

Lotens, W. A. (n.d.). Heat Exchange Through Clothing. Retrieved December 3, 2018, from http://www.iloencyclopaedia.org/part-vi-16255/heat-and-cold/76-42-heat-and-cold/heat-exchange-through-clothing

Lotus, M. (2006, August 09). Latex or Lycra? Facts behind the fibers. Retrieved December 3, 2018, from https://organicclothing.blogs.com/my_weblog/2006/08/latex_or_lycra_.html